Econogon

Build a String of Econogons

by Harold E. Hunley, Jr.

Modeltec, May 1984

Shortly after their purchase of a 2-1/2 inch scale Allen Models Chloe from builder Alfred McCue, Wilburn and Kenneth Wood made several trips to the Roanoke Transportation Museum on Run Days over the Blue Ridge Live Steamers track. Soon, however, they found themselves tiring of pulling passengers on the Museum's riding cars. This was in the spring of 1979.

Wilburn started to look for a prototype car to model in 1-1/2 inch scale ... something that would be simple but in-expensive.

While at work one evening, Wilburn (who is a Carman for the Norfolk & Western RR) took note of an old N&W G-1 class low-side gondola spotted nearby on a siding. After giving it the once over, he decided that it was the car he wanted to build. A few quick measurements and he was set to start a riding car of his own.

He worked in his spare time and produced a riding car that was well built and, just as he wanted it, very inexpensive.

At the May 1979 meeting of the BRLS, Wilburn brought the car for "Show and Tell." By this time it had been finished with trucks and couplers, painted for his Paradise & Little Maple Railroad and numbered 1001.

The gon really made a hit with the club members present, especially when they were told that there were less than ten dollars in the carbody! (1979 prices, excluding trucks and couplers.)

The BRLS Run Day Committee asked Wilburn if he would prepare all parts needed for two of the cars and assemble them during a Rolling Stock Construction Clinic on the Club Run Days, July 28th and 29th, 1979. Wilburn asked this writer to assist him on the project and, of course, he did just that! For the next month and a half, the two were busy preparing for the Run Days.

On the Run Days, all the parts that they had labored so hard to prepare were assembled into riding cars before many Museum patrons.

By the time Labor Day Weekend (1979) came, out rolled the first of the Club's two new blue gondolas. The gon operated very well over the entire weekend, hauling many a passenger. There were, for sure, two very happy and satisfied car builders in the BRLS that weekend!

The second Club Gondola joined the first soon after and they operate at all Run Days on the Blue Ridge Railroad, the name given to the tracksite by members of the BRLS.

Ever since the Club Gondolas made their appearance with Wilburn's original P&LM 1001, there have been many requests for plans and measurements of both the prototype and the models that were built. After five years of service, these gons have required only minor repairs and touch-up paint.

We're proud to bring to you the story and drawings that will be needed to build gondolas such as Wilburn Wood and Harold Hunley have built. As of this time, there are no fewer than six of the gons built ... both high- and low-side versions, and many more under construction by these two Live Steamers.

Riding cars built to these designs are very sturdy and have a low center of gravity. The choice of high or low sides makes these cars suitable for all from toddler to Senior Citizen as far as safety goes. By following the instructions given here, every one can have a nice, long train of passenger hauling gondolas, all well-built and very inexpensive.

Basic Dimensions, Tools and Materials

The dimensions given in these instructions produce a car that is a little wider than a model of the prototype would be in 1-1/2 inch scale. This makes it possible for full-scale people to be seated within the sides of the cars and not on the top edge of the sides. All dimensions can be altered to fit the available wood and type of car you want to build ... high or low sides.

The prototype N&W class G-1 gondola is 40 feet long with low sides (approximately 4 feet 6 inch sides outside measure). The N&W also has a class G-5 gondola that is about 48 feet long with high sides that measure approximately 5 feet 6 inch (outside measure). You can build with either high or low sides and long or short in length.

You'll need the following tools and materials to cut and assemble the main body:

- TOOLS

- Hammer

- hand or power wood saw

- carpenter's square (to check squareness)

- tape measure

- pencil

- MATERIALS

- 4d nails

- 1-1/2 inch roofing nails Ed: sheetrock screws will work better than nails, as they are less likely to work loose

- 3/8, 1/2 and 5/8 inch thick exterior plywood

First, cut the plywood to the following sizes:

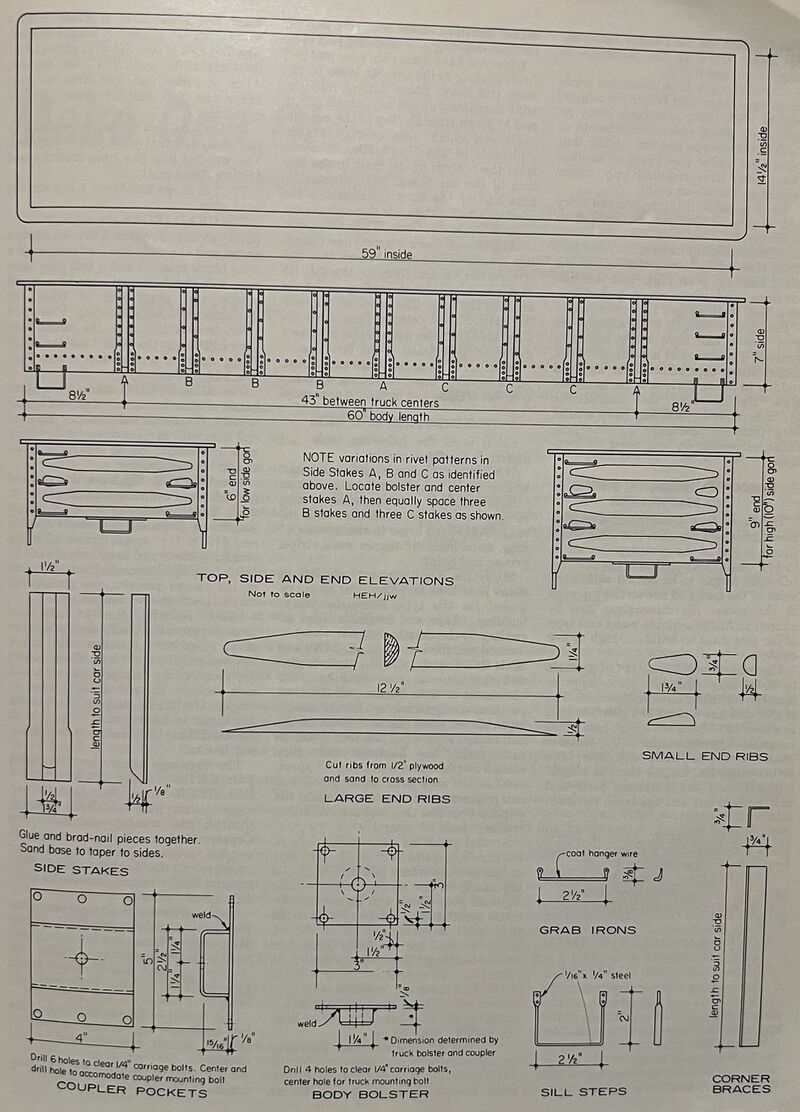

- FLOOR — 1 required 5/8 by 14-1/2 by 59 inches

- SIDES — 2 required 3/8 by 7 by 60 inches

- ENDS — 2 required 1/2 by 6 by 14-1/2 inches

After cutting the plywood, take the two ends, glue and nail to the car floor with 4d nails (5 each end, start at center and work out towards each side). Nail them flush with the ends of the floor. Set the floor and ends aside.

On the car sides (position better side out), measure and mark with pencil the center locations of the side ribs (see rib location drawing - 9 on G-1, 11 on G-5) Once you have done this, glue and nail (with roofing nails) the car sides to the ends and floor. Start nailing into the ends beginning at the top, about 3/4 inch in and 1 inch down from the top of the car side until you check side overlap at the underside of the floor. Then measure from the bottom of the floor to the bottom of the car sides. That dimension, plus half of the floor thickness, is the position line for the nails through the car sides into the car floor. When this point is determined, mark a pencil line the entire length of the side. Where this line crosses the vertical lines for the side rib centerlines, nail (with roofing nails) the sides to the floor. The heads of the roofing nails will be covered later with the side ribs. This line will also be used as a guide for rivet detail at the floor line.

When all of these parts are assembled, you'll have, at least, an oblong open-top box. Set it aside and begin the next step:

Side Ribs and End Ribs

You'll need the following tools and materials for these parts:

- TOOLS

- carpenters hammer

- ball peen hammer

- hand or belt sander

- jig or sabre saw

- tape measure

- MATERIALS

- 1/8 inch paneling scraps

- 1/2 inch plywood scraps

- small brad nails 1/2 inch long

- round-head brass linoleum nails 5/8 inch long

- wood glue

- 1/2 inch square wood strips

- primer and paint

Study the drawings and complete as many Side Ribs and End Ribs as are required for the type Econogon you're building. Shape and assemble them according to the details.

Once you have your Side Ribs and End Ribs ready, you can begin to glue and nail them on your wood box. For placement of Side Stakes and the rivet pattern, see the drawing. Rivets should be as shown when placed in order on the car, except for the bottom four rivets on each stake: the linoleum nails here should be placed no less than 3/4 inch apart.

After the Side Ribs are in place, you can proceed to nail the rivet detail at the outside floor line that was drawn earlier, spacing them 3/4 inch apart.

At this point, all the rooting nails in the car side should be covered ... except at the corners where you still have the big heads of the roofing nails looking right at you. These will be covered by sheet metal angles which can be made from steel or aluminum, 3/4 inch by 3/4 inch by length needed for the style Econogon you're building. Rivets here should be placed 3/4 inch on centers.

The End Ribs are installed with glue and 4d nails. If the nails protrude to the inside of the car, cut these off or brad them with a steel block.

After all the Side Ribs and End Ribs are installed, the next step will be the Top Rail. That is the piece which extends around the entire top of the car sides and ends. This is made from a wood strip 1/4 inch by 1-1/4 inch length needed. The Top Rail is secured with glue and 5/8 inch linoleum nails spaced 4 inch on centers. After the glue has had time to cure, shape the Top Rail as shown on the drawing.

By the time you're this far along, you can really tell just what you're building. The wooden box has been transformed into an Econogon!

The Sill Steps and Grab Irons are the next step.

The Grab Irons are made from ordinary clothes hangers. They are bent to shape and the ends are flattened with a steel block or anvil and a ball peen hammer. File the flattened ends to a round profile and then drill to clear the linoleum nails for mounting. From one Grab Iron to the next, the bends may vary a little but that won't matter much. Place them in a sequence where they won't be noticed.

The Sill Step is made from steel, brass, or aluminum, 1/16 inch by 1/4 inch by length needed. Bend and twist as per drawing and then drill to clear the rivet (linoleum nail) and mount on all four corners as shown on the drawing.

The Center Sill on the original gondolas are ordinary (knot-free) 2 inch by 2 inch by length needed or 2 inch by 4 inch ripped lengthwise. They are mounted with glue and #12 by 1-1/2 inch wood screws after the coupler pockets and body bolsters are in-stalled. Apply the screws from the inside of the car to prevent any protruding screw tips in the passenger area.

Side Bearing blocks are mounted after the trucks are installed to check clearance between the Truck Bolster and the Car Floor. These blocks are mounted to help prevent excessive side rock of the car either loaded or empty. The blocks can be of steel, brass, aluminum or hardwood. The gons built for the BRLS had hardwood Side Bearing Blocks.

The drawings show the Coupler Pockets and Car Body Bolsters. Mount them with 1/4 inch carriage bolts with all bolts passing through the wooden car floor. The Coupler Pocket will have a 5/16 inch or 3/8 inch coupler retaining bolt to suit your couplers and the Body Bolster will have a center hole to match your trucks, probably 3/8 inch or 1/2 inch bolts.

Once you have this all together, prime and paint your Econogon your own personal color scheme and letter it as you wish. Then install your trucks and couplers and take your Econogon out to your track or to your club track and enjoy!